A Complete Guide to Road Safety Barrier Specifications for New Indian Highways

- JANUARY 14, 2026

- By Admin

One mistake in the specification of a highway safety barrier can jeopardise human life, raise the cost of maintenance, and put project stakeholders at regulatory risk. As India expands its National Highway and Expressway networks under the Bharatmala and Gati Shakti programmes in 2026, road safety barriers are no longer a secondary BOQ item. They are an in-house engineering system that follows IRC, MoRTH, and globally set performance standards.

With increased design speeds, heavier freight movements, and stricter third-party audits, selecting the appropriate Crash Barriers system has become one of the most vital technical issues for project authorities, EPC contractors, and consultants. This guide offers a clear India-specific framework aligned with IRC: SP:73-2018, MoRTH specifications, and internationally accepted MASH performance levels, ensuring safety, compliance, and long-term value from tender to execution.

Three Non-Negotiable Engineering Pillars: The 2026 Highway Barrier Framework

Barrier specification as a modern engineering discipline is not a procurement cut-off. All compliant decisions for Indian highway projects launching in 2026 should be based on these three pillars.

Pillar 1: Traffic and Terrain Evaluation

The roadway geometry and traffic behaviour have a direct effect on barrier performance.

Traffic Volume and Design Speed

- Highways with 100 km/h to 120 km/h and ADT over 20,000 vehicles with a heavy commercial truck share above 20% require high containment systems.

Alignment and Risk Zones

- Horizontal curves with radius <250 metres, bridge approaches, medians around toll plazas, and embankments more than 3 metres require improved containment systems according to IRC standards.

- Failure to match the barrier type with the alignment risk is a common cause of post-audit non-compliance.

Pillar 2: Environmental Sustainability and Lifecycle Performance

India’s diverse climate makes durability a specification attribute, not just an enhancement.

Resistance to Corrosion is Compulsory

- Humidity, coastal exposure, industrial pollution, and monsoon cycles significantly affect steel corrosion.

Galvanisation Standards

- Hot-dip galvanisation according to ISO 1461 with a minimum coating mass of 600 g/m² is necessary to ensure a service life exceeding 25 years.

- Lack of sufficient corrosion protection results in premature failure, audit issues, and costly early replacements.

Pillar 3: Performance Conformance and Crash Test

Safety barriers are not supposed to fail in real-life impacts.

MASH as the Global Benchmark

- The Manual of Performance of Safety Hardware has become the universal performance language.

- For most new Indian NH projects, MASH TL-3 is the baseline requirement.

What TL-3 Ensures

- Controlled redirection of passenger vehicles at 100 km/h and heavy trucks at 80 km/h without vehicle vaulting or penetration.

- Performance compliance must always be clearly mentioned in tender documents.

2026 Indian Highway Road Safety Barrier Specification Matrix

The table below can be used as a decision-making reference, correlating design risk, traffic conditions, and durability requirements:

|

Barrier System |

Core 2026 (IRC & MoRTH Aligned) Specifications |

Ideal Application Zones |

Engineering Outcome |

|

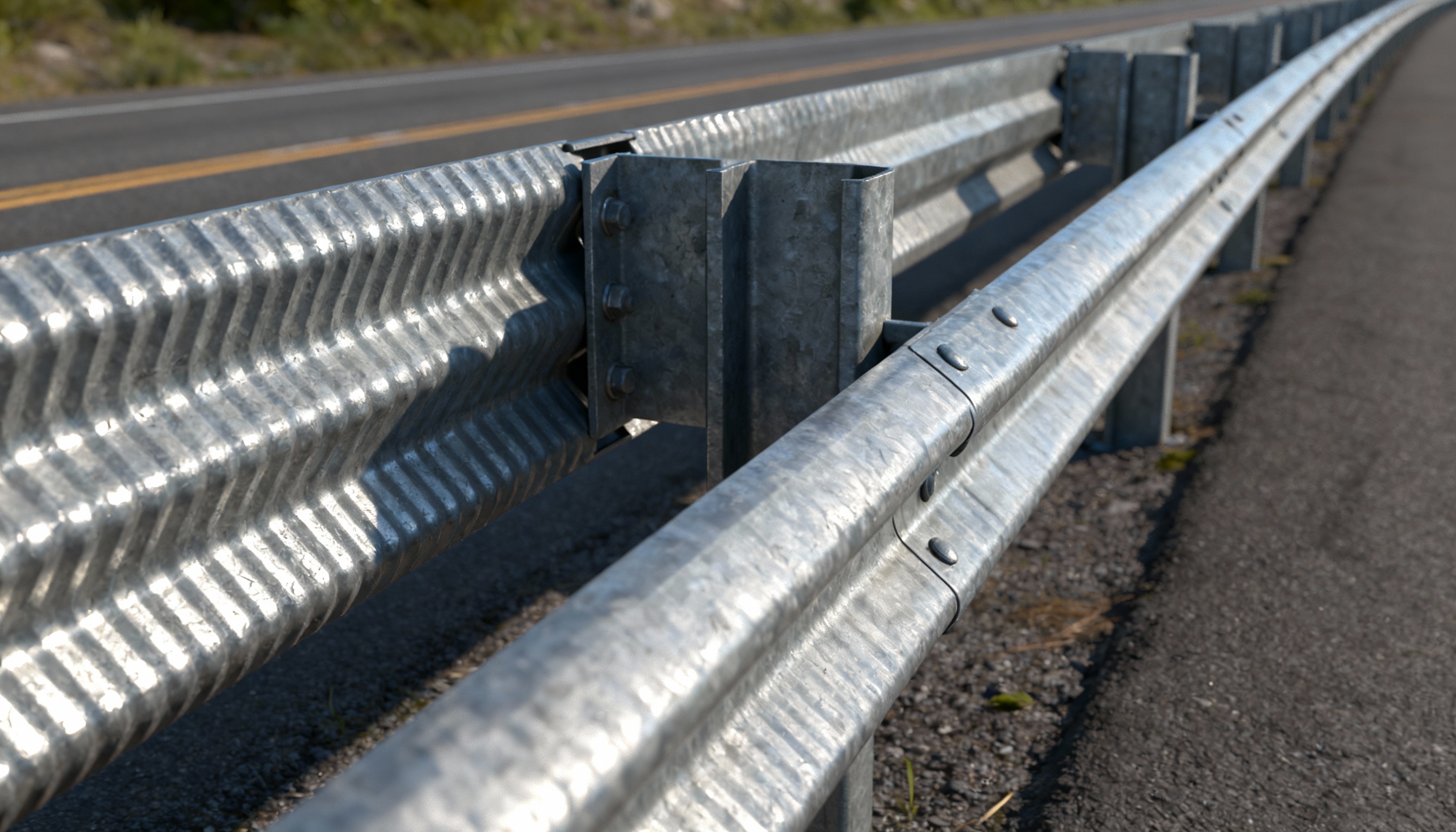

W-Beam Guardrail |

• MASH TL-2 compliant • Minimum yield strength 345 MPa • 3.0 mm thickness • Post spacing 1.9 m |

Long NH with moderate ADT and regulated speeds |

Economical restriction on foreseeable alignments |

|

Thrie-Beam Guardrail |

• MASH TL-3/TL-4 compliant • 4.0 mm thickness • Three-wave high containment profile • Reinforced foundations |

Acute curves, flyovers, bridge approaches, heavy-vehicle routes |

Superior vehicle redirection and high-energy absorption |

|

Concrete Safety Barrier |

• M40 concrete grade • Reinforced steel cage as per IS 456 • New Jersey profile 810 mm height • Zero deflection |

Expressway medians, toll plazas, urban NH corridors |

Long-term and high-density permanent containment with low maintenance |

|

Galvanised Barrier Systems |

• Hot-dip galvanisation ISO 1461 • 600–800 g/m² coating • Representative of steel barriers |

Sea roads, industrial belt, high-rainfall zones |

Durability over the long term and lower cost of life |

Specification Example:

For a high-speed curve on the Mumbai–Pune Expressway expansion, exposed to humidity and heavy freight traffic, a galvanised Thrie-Beam guardrail(Galvanized Crash Barrier) with MASH TL-3 compliance is the technically correct choice.

Common Specification Mistakes in 2026 NH Projects and How to Avoid Them

Even the most experienced project teams can make preventable errors during tender preparation. Recognising these pitfalls and implementing corrective measures ensures safety, compliance, and cost efficiency throughout the project.

Frequent Mistakes:

- Specifying W-Beam barriers for sharp curves or high-speed stretches

- Skipping galvanisation to cut initial costs

- Using generic post spacing without factoring in soil-specific foundation requirements

How to Correct Them:

- Require Thrie-Beam systems for curves with a radius below 250 metres

- Clearly state the galvanisation coating mass in BOQs

- Include foundation depth and embedment details based on geotechnical surveys

Clearly defined specifications not only enhance road safety but also reduce disputes, prevent rework, and smooth audit approvals.

Beyond Barriers: Building a Complete Highway Safety System

Crash barriers are only one part of a fully integrated highway safety ecosystem. For maximum effectiveness, specifications should also cover:

- High-Visibility Road Markings: Use high retroreflective thermoplastic markings for night and monsoon visibility

- Crash-Tested End Treatments: Energy-absorbing terminals at barrier ends to prevent spearing impacts

- Work-Zone Safety Devices: Channelisers, cones, and signage to ensure worker safety during installation and maintenance

Integrated planning guarantees safety continuity across the entire highway corridor.

Develop Highway Launch 2026 Projects with Confidence

Highways developed in India in 2026 need precision, compliance and proven safety planning. Correctly specified Road Safety Barriers reduce accident risk, extend service life, and ensure smooth approvals during technical audits.

At Treadsafe Steel, we provide IRC and MoRTH-compliant barrier solutions for highway authorities and EPC teams based on real site conditions. Our focus is simple: compliant specifications, reliable performance, and long-term safety.

Specify right. Build responsibly. Protect lives.

FAQs

1. What is the IRC code for safety barriers?

The standard IRC code for road safety barriers in India is IRC: SP:73-2018, which covers guidelines for the design, installation, and testing of crash barriers on National and State Highways.

2. What is the NHAI circular for crash barriers?

The NHAI circular provides project-specific directions and mandates regarding crash barrier specifications, including design speed considerations, MASH performance levels, and barrier type selection for National Highway expansions.

3. What are the road safety guidelines in India?

Road safety guidelines in India are framed by IRC and MoRTH. They cover barrier design, alignment risk assessment, environmental durability, crash performance, and installation practices to ensure maximum safety for vehicles and highway users.

4. What is a road safety barrier?

A road safety barrier is a protective system installed along highways to prevent vehicles from leaving the road or crossing medians. Treadsafe Steel products include:

- Metal Crash Barriers / Metal Beam Crash Barrier

- W Beam Crash Barrier / W Beam Metal Crash Barrier

- Thrie Beam Crash Barrier / Thrie Beam Metal Crash Barrier

- Galvanized Crash Barrier

- Road Barriers / Road Safety Barriers / Road Crash Barriers

- Expressway Crash Barrier / Railway Crash Barrier

These are designed for maximum safety, durability, and compliance on Indian highways.