How to Select a Reliable Crash Barrier Supplier for Large-Scale Infrastructure Projects?

- JANUARY 13, 2026

- By Admin

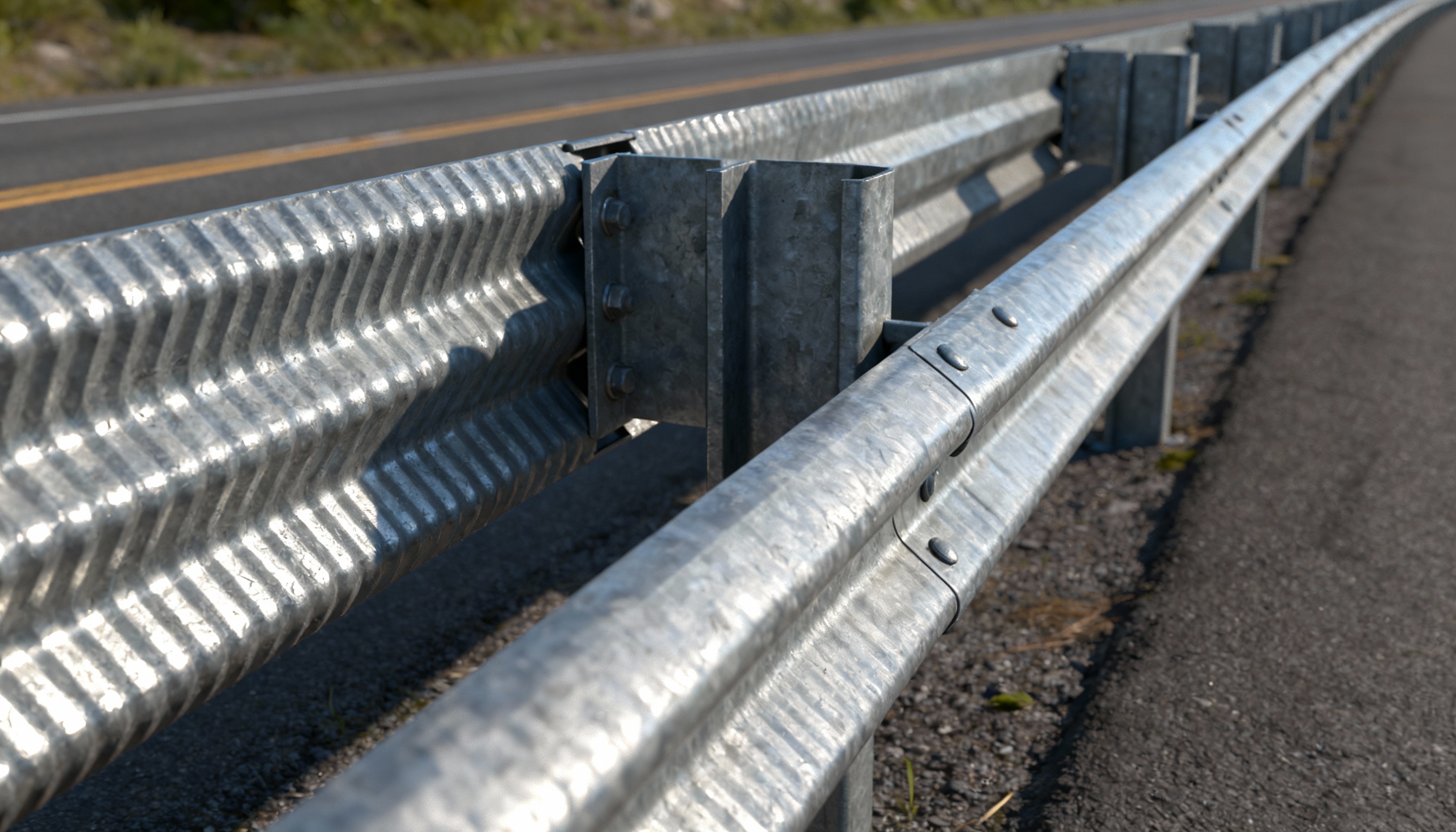

Road safety systems play an important role in large infrastructure development that can work under severe circumstances. One of these systems is a Crash Barriers on road, which is very important in regulating the flow of vehicles when there is an accident and in reducing the extent of impact. The choice of a supplier of such safety equipment is more than just a procurement decision, but a long-term commitment to both the safety of the people and the credibility of the project.

Crash barriers are required to provide consistent performance under different traffic loads of highways, expressways, bridges, and industrial corridors, and under different environmental conditions. A reliable supplier is aware of the technical requirements of infrastructure authorities and provides them with solutions that are neither too strong, flexible nor durable to the point of compromising their compliance requirements.

This guide will provide information on the process of assessment and identification of a supplier of crash barriers who will be able to assist in the implementation of large-scale infrastructure projects with professionalism and reliability.

The Purpose of Crash Barriers in Infrastructure Safety

Crash barriers are safety structures that are designed to absorb impact during a collision and redirect the vehicles out of the hazardous areas. Their performance lies on the correct design, the quality of their materials and precision in their manufacture. Improperly made systems may not work in actual impact cases causing the road people to be at more risk.

Various road conditions require varying designs of barriers. Each of the sharp curves, high-speed corridors, flyovers, and medians will need a specific solution. That is why the experience of suppliers is also as important as the product itself.

What to Consider in a Supplier of Barrier Crashes

Production Strength and Consistency

An effective Crash Barrier Manufacturer should have high-quality checks at all production levels. Standardised testing, in-house fabrication, and sourcing of uniform material make certain that each of the units would perform on any given condition in the real world.

Laws and Confirmation of Oversight

Suppliers must give documentation that establishes that their barriers comply with recognised safety and structural standards. These reports confirm that the system does act in a controlled collision situation and they confirm that the system is reliable during a barrier crash situation.

Infrastructure Scale Projects Experience

Massive projects demand supply on time, batching and logistical alignment. Suppliers who have an established infrastructure history would be in a better position to meet volume requirements without affecting the quality.

Technical and Installation Support

In addition to the manufacturing, a reliable supplier provides information on the choice of the barrier, planning the layout, and the way of installation. This aids in reducing on-site errors and optimization of the long term performance of the system.

Common Types of Crash Barriers Used in Large Projects

A reliable supplier will offer multiple barrier systems and guide decision-makers based on site conditions and traffic behaviour.

|

Barrier Type |

Typical Application |

Performance Advantage |

|

Concrete Crash Barrier |

Medians and bridge edges |

High impact resistance and long service life |

|

W Beam Crash Barrier |

Highways and curves |

Controlled flexibility and energy absorption |

|

Metal Beam Crash Barrier |

Expressways and service roads |

Cost-effective and scalable safety solution |

|

Composite Barrier Systems |

Complex road layouts |

Balanced strength and adaptability |

Each system behaves differently during an impact event, which is why selection should never be generalised across all road sections.

The Approach That Treadsafe Takes Towards Manufacturing Crash Barriers

Treadsafe is a company that specialises in the creation of engineered systems of safety barriers that cooperate with the modern infrastructure requirements. The company has focused on accuracy in manufacturing, strong material choice, and performance-based designs that help to achieve long term road safety objectives.

Their solution focuses on robustness, impact behaviour, and flexibility in various road conditions, which is why their solutions are also applicable to both new developments and safety enhancements. These include rigid systems such as concrete crash barrier solutions and flexible options like w beam crash barrier and metal beam crash barrier systems, depending on site conditions.

The Reason Why Impact Performance Should Not Be Neglected

Each safety system should be tested according to its performance during a real collision. In an actual barrier crash case, the system should absorb the energy slowly, be structurally sound and need not allow the vehicles to cross to the other traffic or dangerous areas.

When suppliers are aware of these forces, they are able to produce products that operate in a predictable manner as opposed to basing their strength on theoretical strength alone. This directly affects the safety outcome of every crash barrier on road installation.

Errors to Be Avoided When Choosing a Supplier

- Selecting suppliers on the basis of pricing

- Disregard of impact performance data in the real world

- Choosing small product lines that are not compatible with different road conditions

- Ignoring the long term maintenance

- Not measuring material corrosion resistance and finish quality

The prevention of such mistakes will contribute to the fact that safety installations will stay effective at least during the period during which they are supposed to be in operation.

Final Perspective

The identification of an appropriate crash barrier provider is a strategic move that determines directly the safety on the road and the durability of the infrastructure. Project planners can achieve this by concentrating on the quality of manufacturing, impact performance and the expertise of the suppliers in order to have a reliable coverage in the long run in terms of safety systems.

Safety compliance through a collaboration with an experienced company such as Treadsafe assists infrastructure projects to be reliable in the long-term and in terms of performance.

FAQs

Q1. What is the meaning of a crash barrier?

A crash barrier is a road safety system designed to reduce the impact of accidents. It absorbs collision energy and guides vehicles back onto the roadway to prevent them from entering dangerous zones or opposing traffic.

Q2. How many types of crash barriers are there?

Crash barriers come in several types, including concrete barriers, W beam barriers, and metal beam barriers. Each type is chosen based on road design, traffic speed, and safety requirements.

Q3. What are the specifications of a crash barrier?

Specifications typically include material quality, height, thickness, post spacing, corrosion protection, and impact performance. Trusted Crash Barrier Manufacturers like Treadsafe follow strict standards for reliable safety.

Q4. How do crash barriers work?

Crash barriers work by absorbing and dispersing the energy from a collision. This controlled deformation reduces impact force and redirects vehicles safely, minimizing damage and improving road safety.